Design & Detailing

SOLIDWORKS

Through the use of SolidWorks Premium, and SolidWorks Simulation Professional, OST Services can now offer Finite Element Analysis, and 3D Modeling services to our customers. Finite element analysis (FEA) is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. After generating a 3D model, the Finite element analysis shows whether a product will break, wear out, or work the way it was designed.

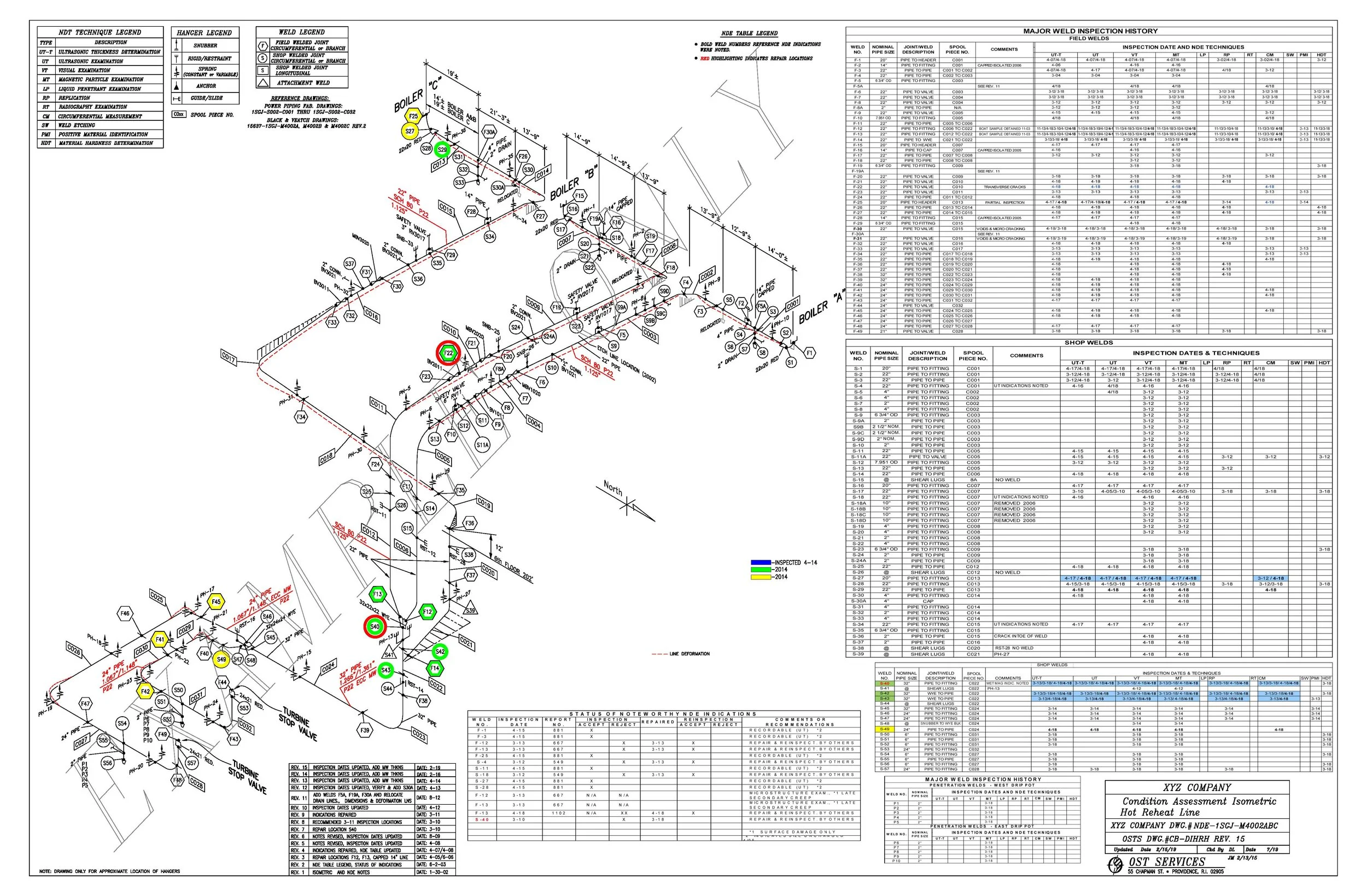

CONDITION ASSESSMENT

An isometric drawing illustrating the basic system configuration of the pipe system will be developed. The drawing will incorporate all known data from combined spool piece drawings as well as noting all indicated welds. If the Condition Assessment drawing is developed in conjunction with a stress analysis, all weld node points will be carried over to the drawing. Data tables will be developed and inserted into the CAD drawings allowing for continuous updating to track past and present NDE efforts.

The drawings will prove to be of significant value in managing pipe inspections (NDT methods and results, locations and intervals between inspections) along with consolidating general piping information.

A variety of optional information can be incorporated into the drawings. These options include, but are not limited to, the following, all of which may impact pricing:

Pipe stress results

Pipe support record sheets

Insulation abatement/materials and locations

Small bore valve inventory and replacement data base